BV-10

The BV-10 offers precision beveling of micropipette tips between 0.1 and 100 µm. The unique abrasive plate drive system is vibration free for greater control of the beveling process. Beveling can be accomplished very rapidly and produces consistent tip diameters using the techniques as described by Brown and Flaming, Science, August 1974, Vol. 185.

Intracellular recording electrodes can benefit from beveling because of:

- A reduction in the tip diameter by creation of the sharp point on the electrode

- A lowered electrical resistance of the electrode due to the larger cross sectional area of the lumen.

This greatly facilitates penetrating and holding very small or difficult cells. Microinjection needles also benefit from beveling by promoting entry into cells with minimal damage while at the same time enhancing the flow of material through the needle.

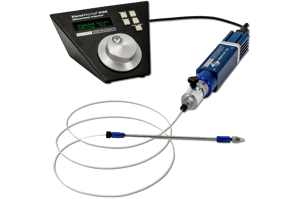

The basic beveling system consists of a stationary pedestal, optically flat to a half wave (250 nm), surface mounted on a heavy baseplate. This serves as a bearing for an abrasive coated glass grinding plate, which is also flat to half a wave. The flat abrasive plate is coupled to a low vibration, slow-speed motor by means of magnetic fields to provide a wobble-free flat grinding surface. The abrasive plates are fabricated with a proprietary process which insures a consistent abrasive coating.

A 2-axis micromanipulator holds the pipette to be beveled and permits controlled advancement onto the abrasive surface. The bevel angle and speed of advancement are adjustable. An LED lamp with a gooseneck enhances the beveling operation by providing sharp illumination of the abrasive plate and pipette.

The basic system is completed with two abrasive plates of your choice, a wick with holder (for wet beveling), pedestal oil, degreasing fluid, and manual.

Two options are available for monitoring the beveling process, an 40X stereo microscope and an electrode impedance meter. Depending on your research application, one or both of these options may be desirable. For all micropipette applications, the swing mounted microscope enhances your control of pipette advancement onto the abrasive plate and allows for viewing of the beveling operation (scope resolution is not sufficient for viewing the actual bevel except in the case of very large tips). For microelectrode applications, the impedance meter is used to monitor the tip resistance during the beveling operation. The meter is an analog design, offering three resistance ranges (0 - 10, 0 - 100, 0 - 500 MOhm). Measurements are made at 12 Hz to minimize capacitive contributions to the impedance measured and provide a near-true DC resistance value. A rapid roll-off is used to reduce 50/60 Hz interference, allowing operation in a laboratory environment without screening.

- Features

- Specifications

- Product Information

- Part #

- Vibration-free, magnetically coupled beveling surface

- Abrasive surface optically flat to a half wave (250 nm)

- Finest abrasive surface commercially available

- Synchronous clock motor insures stable rotation rate

- 7 lb aluminum baseplate adds additional dampening

- Integrated LED lamp

- Robust micromanipulator controls bevel angle and advancement

TECHNICAL SPECIFICATIONS

Beveling Range

0.1µm through 100µm finished electrodes depending on abrasive plate used

Grinding Surface Variation

Less than 1.0 µm

Grinding Speed

60 RPM

Beveling Angle Range

5-90 degrees - adjustable

Micromanipulator

Coarse drive: 0.075 in / dial revolution

Fine drive: 0.0004 in / dial revolution

Dimensions

19 in x 9 in x 8 in | 48 cm x 22 cm x 20 cm

Weight

30 lbs | 14 kg

Electrical

110-120v / 200-240v | 50/60 Hertz power line

RoHS Certified

CE Certificate

Part Number > BV-10

International prices vary by country. Please contact your local distributor or Sutter Instrument for a quotation.

| Part Number | Description |

|---|---|

| BV-10-B | Micropipette beveler basic system* |

| BV-10-C | BV-10-B with electrode impedance meter |

| BV-10-D | BV-10-B with 40X stereo microscope |

| BV-10-E | BV-10-B with impedance meter and 40X stereo microscope |

| BV-10-N | BV-10-B with 40X stereo microscope for NSOM, nano-ESI |

* Includes micromanipulator, reference wick, reference wick holder, pedestal oil, degreaser, manual, and two abrasive plates of your choice.

ACCESSORIES

| Part Number | Description | |

|---|---|---|

| BVM-CE | Electrode impedance meter with active and reference lead | |

| BV-10S | 40X stereo microscope | |

| 104C | Diamond abrasive plate - coarse (5.0 µ to 50 µ tip sizes) | |

| 104D | Diamond abrasive plate - fine (2.0 µ to 20 µ tip sizes) | |

| 104E | Diamond abrasive plate - very fine (0.7 µ to 2.0 µ tip sizes) | |

| 104F | Diamond abrasive plate - extra fine (0.2 µ to 1.0 µ tip sizes) | |

| 007 | Degreaser (bottle) | |

| 008 | Beveler pedestal oil | |

| O740124 | 20X eyepiece | |

| REPLACEMENT PARTS | ||

| 101 | 6-inch reference lead (body to meter) | |

| 102 | 2-inch active lead (platinum to pipette) | |

| X050300 | Reference wick | |

| M100019 | Reference wick holder | |

| H906100 | Drive belt | |

| PEDESTAL | Pedestal plates (top and bottom) | |

Applications

- Pronuclear microinjection

- Embryonic stem cell transfer

- Nuclear transfer (ES cell)

- (ICSI)

- Piezo-assisted sperm-mediated transgenesis

- Nuclear transfer (NT)

- Adherent cell microinjection

- Drosophila injection

- C. Elegans injection

- Zebrafish injection

Related Products

Enhance capabilities and take your lab to the next level with more products from Sutter Instrument.

Air-based microinjector for transgenic mammal workstations.

Read More

A versatile motorized microinjector with a wide range of microinjection applications.

Read More

Micropipette puller with applications in electrophysiology and microinjection.

Read MoreNeed help finding the right product?

Whether you're looking for a quote, or unsure of which Sutter product best fits your application, our knowledgeable experts can help answer your questions, and customize systems to fit your needs.